Key Takeaways:

- Abrasion testing evaluates the durability and performance of materials subjected to wear and tear.

- It helps assess the lifespan, durability, and quality of products in various industries.

- Abrasion testing can be classified into dry and wet methods.

- Choosing the right abrasion testing method depends on factors such as material type and intended use.

- Interpreting test results helps understand material performance and improve product design.

Abrasion testing is a vital process used in various industries to evaluate the durability and performance of materials subjected to repetitive wear and tear. This comprehensive guide will provide you with a deep understanding of abrasion testing, its types, how to choose the right method, interpreting test results, and its significance in improving product performance.

What is Abrasion Testing?

Abrasion testing is a method used to determine the resistance of a material’s surface to wear due to friction. It involves subjecting the material to controlled abrasive forces, simulating real-world conditions. By conducting abrasion tests, manufacturers can assess the lifespan, durability, and quality of their products.

Understanding the Basics of Abrasion Testing

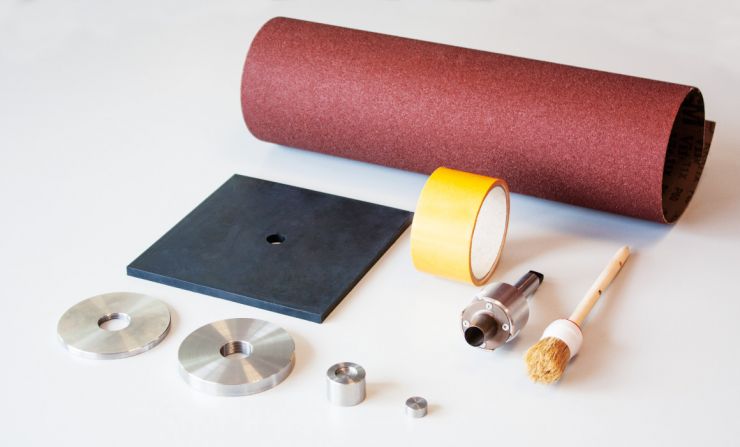

In an abrasion test, a sample material is typically exposed to an abrasive surface or subjected to rubbing, scratching, or repeated contact with another surface. The test measures various parameters, such as weight loss, surface damage, or changes in appearance, to evaluate the material’s resistance against abrasion.

The Importance of Abrasion Testing in Various Industries

Abrasion testing plays a crucial role in multiple industries, including automotive, aerospace, textile, manufacturing, and consumer goods. Understanding a material’s abrasion resistance is vital for predicting its performance in real-world applications and ensuring product longevity. For example, in the automotive industry, abrasion testing helps assess the durability of car paint, interior fabrics, and upholstery against daily wear and tear.

Types of Abrasion Testing

Abrasion testing can be classified into two main categories: dry abrasion testing and wet abrasion testing.

Dry Abrasion Testing: Exploring the Various Techniques

Dry abrasion testing involves subjecting the material to abrasive forces without the presence of any liquid. Various techniques are commonly used in dry abrasion testing, including the Taber Abrasion Test, Martindale Abrasion Test, and the Falling Sand Test. Each technique measures different aspects of abrasion resistance, such as surface loss, pilling, and scratching.

Wet Abrasion Testing: A Deep Dive into the Methods and Applications

Wet abrasion testing simulates abrasive wear under moist or liquid conditions. This type of testing is particularly relevant for materials exposed to wet environments or those that come into contact with liquids during use. Common wet abrasion tests include the Wet Rub Test and the Crockmeter Test, which assess colorfastness and color transfer resistance of textiles and coatings.

Comparing Dry and Wet Abrasion Testing: Pros and Cons

Both dry and wet abrasion testing have their advantages and limitations. Dry abrasion testing provides insights into the material’s resistance against dry wear conditions, while wet abrasion testing evaluates its performance in wet or liquid environments. It is essential to consider the intended application when selecting the appropriate abrasion testing method.

Choosing the Right Abrasion Testing Method

Choosing the right abrasion testing method requires careful consideration of several factors, including the material type, intended use, regulatory requirements, and testing equipment availability.

Considerations for Selecting the Best Abrasion Testing Technique

When selecting an abrasion testing technique, it is crucial to consider factors such as the type of material, the expected mode of wear, the desired testing conditions (dry or wet), and the required accuracy and precision of the test results.

Understanding the Factors that Impact Abrasion Test Results

Achieving accurate and reliable abrasion test results requires understanding the factors that can influence the testing outcome. Variables such as the abrasive material, load, speed, and test duration must be carefully controlled to ensure consistent and repeatable results.

Case Studies: Real-World Examples of Effective Abrasion Testing

Examining real-world case studies can provide valuable insights into the effectiveness of different abrasion testing methods and their impact on improving product performance. These case studies highlight the importance of selecting the right testing technique for specific materials and applications.

Interpreting Abrasion Test Results

Interpreting abrasion test results is crucial for understanding the material’s performance and making informed decisions regarding product design and development.

Analyzing and Interpreting Abrasion Resistance Data

Interpreting abrasion resistance data involves analyzing parameters such as weight loss, volume loss, surface damage, or changes in appearance. Comparing test results against established standards or previous test data can provide insights into the material’s durability and predict its performance in real-world applications.

Understanding the Significance of Abrasion Test Standards

Abrasion test standards, such as ASTM D4060 (Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser) or ISO 12947 (Textiles – Determination of the abrasion resistance of fabrics by the Martindale method), ensure consistency and reliability across different testing laboratories and facilitate fair comparison of materials. Understanding these standards is crucial for accurate interpretation of test results.

How to Use Abrasion Test Results to Improve Product Performance

A thorough analysis of abrasion test results enables manufacturers to identify weaknesses and areas for improvement in their product design and materials selection. It helps optimize product performance, increase durability, and reduce the risk of premature failure or customer dissatisfaction.

This complete guide provides a comprehensive understanding of abrasion testing, including its types, selecting the appropriate method, interpreting test results, and leveraging those results to enhance product performance. By implementing proper abrasion testing procedures, manufacturers can ensure their products meet the highest quality standards and provide long-lasting satisfaction to consumers.